Series 12D

Series 12D Imo pumps are intended for relatively high pressure service on petroleum or similar viscosity liquids. Typical applications include crude oil pipeline service, fuel atomization for burning in a steam boiler, fuel injection for combustion gas turbines, fluid power service on hydraulically operated machinery, gas sealing in centrifugal compressors and hydrostatic bearing support.

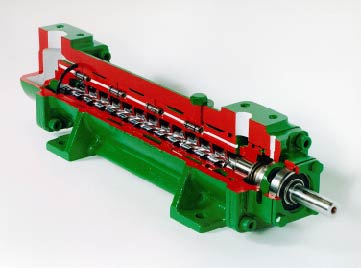

These pumps are hydraulically balanced in both the axial and radial directions which eliminates bearing loads due to discharge pressure. The single bearing is external to the liquid pumped and does not rely on the lubricating qualities of the pumped liquid. The single mechanical seal is exposed only to inlet pressure. Very low airborne noise levels are normal for Imo three screw positive displacement pumps as are high operating efficiencies and non-pulsating delivery of flow.

12D SERIES |

Nominal flow rate, GPM/LPM, at 2200 PSI (152 BAR), 200 SSU (43 CST) |

|||||

SPEED RPM |

||||||

Size |

3500 |

2900 |

1750 |

1450 |

1150 |

960 |

106 |

12/45 |

9/35 |

4/15 |

- |

- |

- |

118 |

17/66 |

14/51 |

6/23 |

- |

- |

- |

137 |

28/107 |

22/84 |

11/40 |

8/29 |

- |

- |

156 |

43/165 |

35/131 |

18/67 |

13/50 |

9/34 |

- |

187 |

77/293 |

62/235 |

33/125 |

25/96 |

18/67 |

13/49 |

218L |

101/383 |

81/308 |

44/166 |

34/128 |

24/91 |

18/67 |

218 |

126/479 |

102/387 |

56/211 |

44/165 |

32/119 |

24/90 |

250 |

191/725 |

155/588 |

86/326 |

68/257 |

50/189 |

38/145 |

275E |

217/822 |

176/667 |

98/370 |

77/292 |

57/215 |

44/166 |

275 |

- |

209/792 |

117/442 |

93/351 |

69/260 |

53/202 |

312P |

- |

248/939 |

140/529 |

112/422 |

83/315 |

65/247 |

312 |

- |

313/1186 |

178/673 |

142/539 |

107/406 |

85/321 |

350 |

- |

- |

255/966 |

206/778 |

156/590 |

125/472 |

400P |

- |

- |

309/1169 |

250/945 |

190/721 |

153/578 |

Series 12D Specifications

Casing- High shock capacity ductile (nodular) iron. Cast steel optional, sizes 118-218.

Rotor Housing- Pearlitic gray iron. Special bimetallic housings available in some sizes for low viscosity, high pressure services.

Power Rotor- Alloy steel, nitride hardened and thread ground.

Idler Rotors- Pearlitic gray iron, induction hardened and thread ground for sizes 106 through 187; alloy steel, nitride hardened and thread ground.

Gaskets- Cellulose and non-asbestos fiber.

Seal & Bearing- Type B: Buna N bellows mechanical seal, Buna N o-rings and standard external, permanently grease packed, deep groove ball bearing- recommended for distillate fuels and lubricating oil or hydraulic fluids. Type H: Positive drive mechanical seal, fluoroelastomer o-rings and external high temperature, permanently grease packed, deep groove ball bearing.

Accessories- Completely mounted, built to order pump/driver assemblies are available with baseplates, ANSI RF spool pieces, NEMA 'C' face adapters.

Outlet Pressure- 2200 PSIG (152 BAR) maximum for lube, seal and hydraulic oils. 1500 PSIG (103 BAR) maximum for distillate, residual and crude oils. Minimum recommended differential pressure is 40 PSI (2.8 BAR).

Inlet Pressure- Type B & H: 75 PSIG (5 BAR) maximum, distillate fuel, lube- sizes 106-187. 50 PSIG (3 BAR) maximum, distillate fuel, lube- sizes 218-400. Type H: 40 PSIG (2.7 BAR) maximum, residuals and crude oil- sizes 106-187. 10 PSIG (0.7 BAR) maximum, residuals and crude oil- sizes 218-400

Viscosity- 33 SSU (2.0 CST) minimum. Type B: 3000 SSU (650 CST) maximum (consider cold start). Type H: Viscosities above 3000 SSU (650 CST)

Temperature- Type B: 0 to180°F (-18 to 82°C). Type H, sizes 106-187: 0 to 250°F (-18 to 121°C) for <1800 RPM, 0 to 225°F (-18 to 107°C) for > 1800 RPM. Sizes 218 and up: 0 to 200°F (-18 to 93°C).

Drive- Direct only. Magnetic Drive configurations also available.

Rotation- Clockwise facing pump shaft . Consult Imo for counterclockwise.

Mounting- May be foot mounted in any orientation. Flange mounting optional for certain applications.

Filtration- Inlet strainers are required to keep contaminants and abrasives out of the pump. They must be selected in consultation with the strainer vendor to prevent pump starvation. Normally, 60 mesh (0.01 inch- 238 micron) for light and 1/8-3/16 inch (3-5mm) openings for heavy oils are recommended.

Maximum Speed- Do not exceed 1800 RPM pumping residual fuels or crude oil due to the presence of abrasives and contaminants:

| Size: | 106 | 118 | 137 | 156 | 187 | 218 | 250 | 275 | 312 | 350 | 400 |

| RPM | 4400 | 4400 | 4400 | 4400 | 4400 | 3600 | 3600 | 3000 | 2500 | 2500 | 2500 |

* Assumes minimum inlet pressure requirements are met.

12D-118 above is typical of sizes 106 through 187 having 4-bolt socket weld inlet and outlet flanges (mating flanges included with pump). Larger sizes have ANSI flanged inlet connections.