Series 3E

Series 3E pumps are provided for differential pressures to 150 PSIG (10 Bar) and flow rates to 100 GPM (375 L/M). Mountings include foot or flange. Casing materials are either cast iron or steel. These three screw pumps are used for fuel oil transfer and burner services, machinery lubrication and other industrial pumping applications. Units without shaft seals can operate at very high speeds on lubrication services when drive by the machine being lubricated. 3E series pumps are also available in canned motor/pump configurations up to 6 HP (4.5 kW).

SERIES |

||||||

Size |

||||||

87P |

||||||

87 |

||||||

95 |

||||||

118P |

||||||

118 |

||||||

143J |

||||||

143 |

||||||

162 |

||||||

187Y |

||||||

187M |

||||||

187 |

||||||

200 |

||||||

Series 3E Specifications

Casing- Pearlitic gray iron. Cast steel optional in all sizes.

Rotor Housing- Pearlitic gray iron. Replaceable in all steel case models plus all versions of the 187/200 case size.

Power Rotor- Alloy steel.

Idler Rotors- Pearlitic gray iron.

Gaskets- Cellulose and non-asbestos fiber.

Seal & Bearing- Type B, sizes 87 through 95: Positive drive mechanical seal, Buna N o-rings and standard external, permanently grease packed, deep groove ball bearing for services up to 180°F (82°C) and/or 25,000 SSU (5400 CST). Type B, sizes 118 through 200: Buna N bellows friction drive mechanical seal, Buna N o-rings and standard external, permanently grease packed, deep groove ball bearing- recommended for distillate fuels and lubricating oil or hydraulic fluids. Type H, sizes 118 through 200: Positive drive mechanical seal, fluoroelastomer o-rings and external high temperature, permanently grease packed, deep groove ball bearing- recommended for residual oils and all applications above 3000 SSU (650 CST). Type I: Integral flange mounted pump with sleeve bearing in lieu of a ball bearing and no shaft seal. For applications where pump shaft is within driving machinery enclosure allowing internal return to sump of shaft leakage. Type N, cast iron cased, flange mount, sizes 118 through 200 only: Positive drive, balanced mechanical seal, neoprene o-rings, carbon on carbide sealing faces and external, permanently grease packed, deep groove ball bearing. For applications requiring higher inlet and discharge pressures.

Accessories- Completely mounted, built to order pump/driver assemblies are available with baseplates, ANSI RF spool pieces, NEMA ‘C’ face adapters.

Outlet Pressure- 150 PSIG (10.3 BAR) maximum for types B, H and I. 350 PSIG (24.1 BAR) maximum type N providing differential pressure does not exceed 150 PSI (10.3 BAR).

Inlet Pressure- 25 PSIG (5 BAR) maximum for types B, H and I. 300 PSIG (17.2 BAR) maximum for type N.

Viscosity- Type B and I: 33 to 3000 SSU (2.0 to 650CST). Type H: 33 to 25,000 SSU (2.0 to 5400 CST). Type N: 60 to 5000 SSU (10 to 1100 CST).

Temperature- Type B: 0 to180° F (-18 to 82° C) Type H, I and N: 0 to 250° F (-18 to 121° C).

Drive- Direct only. Available as a canned motor/pump as well.

Rotation- Clockwise facing pump shaft . Counterclockwise optional on all but type N pumps and the 187M and 187Y sizes.

Mounting- May be foot mounted in any orientation.

Connections- All iron cased pumps and steel cased pumps sizes 87 through 95 are NPT connections. All other steel cased pumps have SAE 4-bolt socket weld flanges that are provided with the pump.

Filtration- Inlet strainers are required to keep contaminants and abrasives out of the pump. They must be selected in consultation with the strainer vendor to prevent pump starvation. Normally, 60 mesh (0.01 inch- 238 micron) for light and 1/8-3/16 inch (3-5mm) openings for heavy oils are recommended.

Maximum Speed- Do not exceed 1800 RPM pumping residual fuels, crude oil due to the presence of abrasives and contaminants:

| Size: | 87-95 | 118P | 118 | 143J | 143 | 162 | 187Y | 187M | 187 | 200 |

| Types B & H | 5000 | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 | 3800 |

Type N |

3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 | 3600 |

Type I |

8000 | 8000 | 6500 | 7000 | 5500 | 4800 | 4800 | 4500 | 4250 | 4000 |

* assumes minimum inlet pressure requirements are met

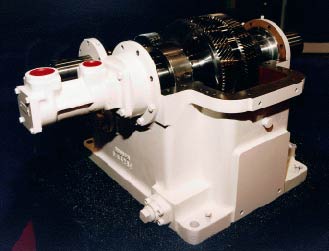

The flange mounted 3E pump provides lubrication oil flow to a speed increaser gear. It is driven from an otherwise unused shaft of the gear box. The bottom of the gear box acts as the lube oil sump. This version 3E pump has no shaft seal and a small amount of leakage from the pump shaft area drains back into the sump area.

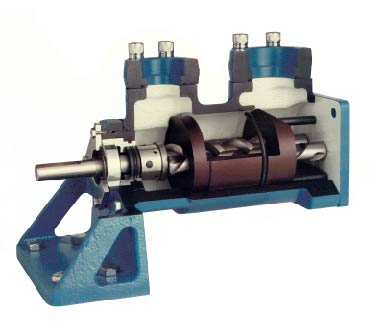

Foot mounted, steel cased 3E pump with replaceable iron housing (liner), mechanical seal and mating SAE 4-bolt socket weld flanges.

Foot mounted, steel cased 3E pump with replaceable iron housing (liner), mechanical seal and mating SAE 4-bolt socket weld flanges.